Advancing Warehouse Management with Voice Picking Software

Set new productivity and accuracy standards in voice-directed warehousing by implementing the latest AI technology.

Are you looking for an efficient solution to optimize your warehouse management? Look no further than Lucas Systems’ Voice Picking Software. Our AI-driven system, Jennifer™, transforms warehouse work, delivering immediate improvements in productivity and accuracy.

Long before Alexa and Siri, Jennifer™ was making work easier and faster for tens of thousands of workers on five continents. Combine voice, scanning, and vision to improve the end-to-end execution of warehouse tasks. Upgrade to Lucas Systems’ Voice Picking Software and experience the benefits of our AI-driven solution. Contact us today to learn more and schedule a demo.

Voice-Directed Warehousing Optimization

Our picking software is powered with unique AI-based intelligence in Jennifer™, which adapts and optimizes processes in your warehouse. Jennifer™ supports technologies such as barcode scanning, smart glasses, and RFID to help automate manual, hands-on processes in your warehouse.

How the Lucus Voice Picking Software Works

Voice-directed software establishes an efficient automation process that allows for eyes-up, hands-free picking. The process is straightforward. Pickers wear headsets with an industrial microphone that connects to a mobile device running the voice application.

As the imported orders come in from your current enterprise or warehouse management systems, or resource planning software, they are recorded, sequenced, and released for processing. The application’s voice tells the picker where to go and what to do, such as the warehouse picking a location and the quantity of the item to pick. The voice picking application includes speech recognition software that recognizes and interprets the order picker’s spoken responses and can feed information into the system.

Once the voice-picking system directs the operator to a particular area in the warehouse, the operator offers numbers to verify that they have reached the correct aisle, section, and bin. The voice-picking system will verify the area and then give the operator the pick quantity, which the operator verbally confirms.

Finding the Most Direct Path

Once picking is completed, the system will send the operator to the next pick location. Throughout the process, the system optimizes the pick path to maximize efficiency and minimize warehouse walking. Many voice-picking systems integrate with existing warehousing systems. In this case, the voice-picking system sends real-time updates to the host system, indicating completed picking, batch completion, and other updates.

Streamline Your Processing with Lucas Systems’ Voice Picking Software

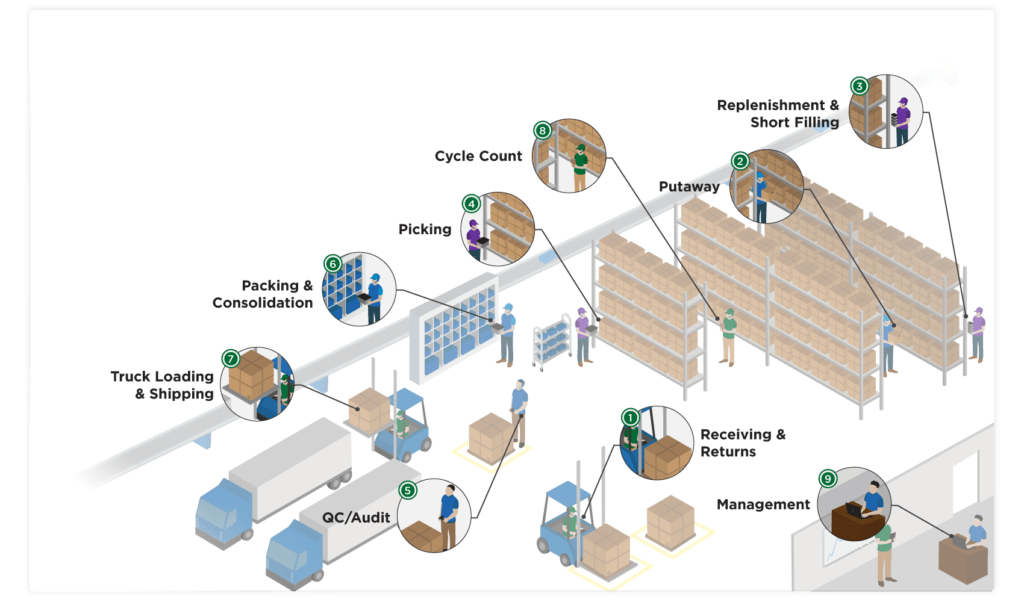

Voice-picking systems are increasingly used in warehouses to streamline operations. Today’s voice-directed applications often incorporate complementary technologies like barcode scanning or RFID. Furthermore, voice systems are now used to automate any manual, hands-on process in the warehouse, including receiving, putting away, replenishment, cycle count, sortation, packing, cross-dock, loading, etc.

Discover How the Jennifer Voice Picking Warehouse System Can Boost Your Business

Implementing voice-picking systems can result in immediate improvements in hourly pick rate and work pace, heightened accuracy, and reduced labor hours. With shorter training times, increased productivity, and improved safety, you’ll experience greater employee satisfaction and decreased employee turnover.

With Lucas’s voice-directed warehousing and voice picking software, you can transform your warehouse operations and improve the end-to-end production of tasks. Lucus voice picking software is used by tens of thousands of workers on five continents, delivering customized improvements quickly and accurately. The software is easy to learn and use, making it simple for your team to adapt and start seeing results immediately.

Are you considering using voice picking in your warehouse? Our experienced team includes industry leaders who can help improve your business processes and productivity. Contact us today!

Frequently Asked Questions

Get Started With These Helpful Resources

Voice Picking Software Selection Guide

This guide dives into determining whether voice is right for your warehouse, key benefits and features, hardware options, WMS and ERP integrations, and system pricing and implementation costs.

Voice Picking Software Selection Guide

This guide looks in depth at how different approaches to implementing voice determine the magnitude of productivity gains any facility may achieve. Use the guidelines in this paper to estimate the potential results in your DC.

We helped Baptist Health, a leading healthcare provider, double picking productivity.

“The previous average picking rate in the LUM area was 50-56 lines per hour (LPH). Today it is 100-110. That is a 100% improvement, and in bulk picking, the number is about 20 percent.”

We helped Apex Tool Group, a leading manufacturer of hand and power tools, operate with 10% fewer man hours.

“You rarely implement a new system and have users tell you ‘It’s made my life so much easier!’ Making the processes better for associates makes them more productive. And that’s better for the business.”

“The previous average picking rate in the LUM area was 50-56 lines per hour (LPH). Today it is 100-110. That is a 100% improvement, and in bulk picking, the number is about 20 percent.”

“You rarely implement a new system and have users tell you ‘It’s made my life so much easier!’ Making the processes better for associates makes them more productive. And that’s better for the business.”