Warehouse Optimization Tools

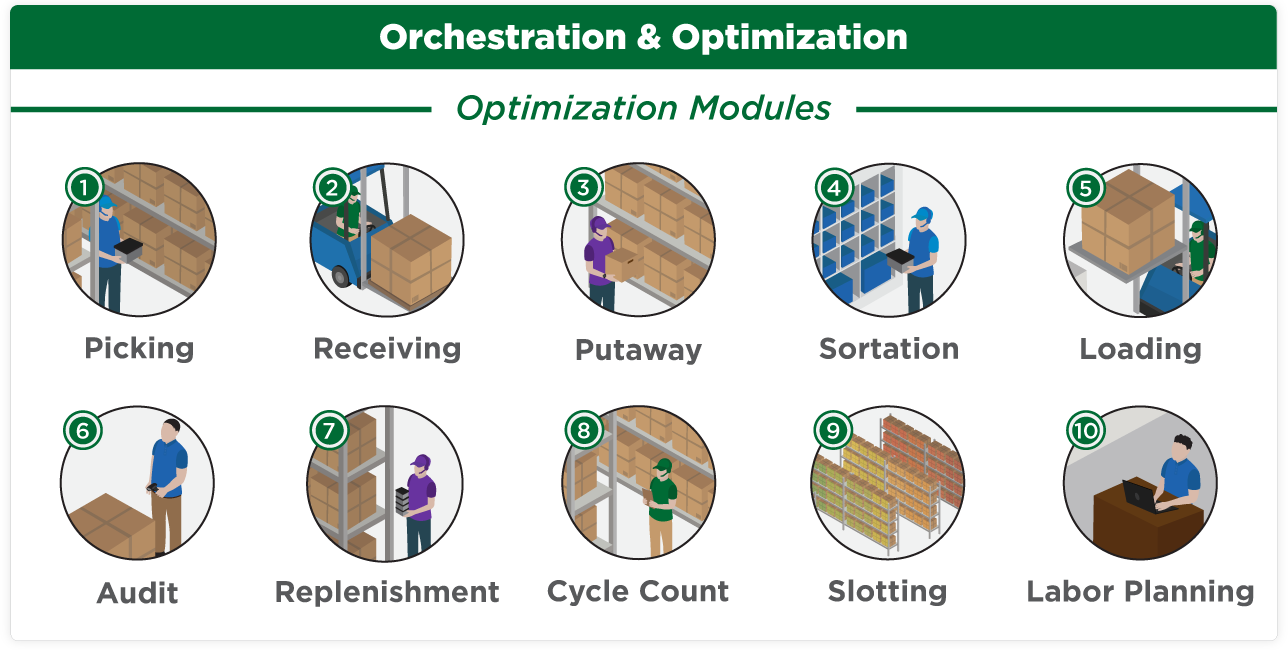

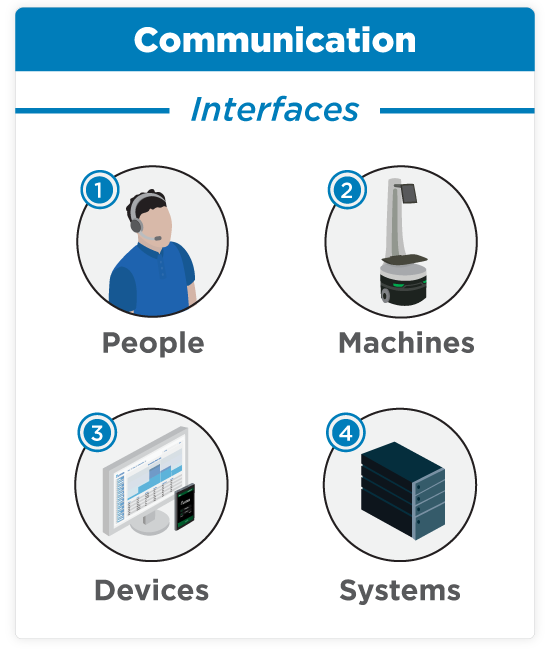

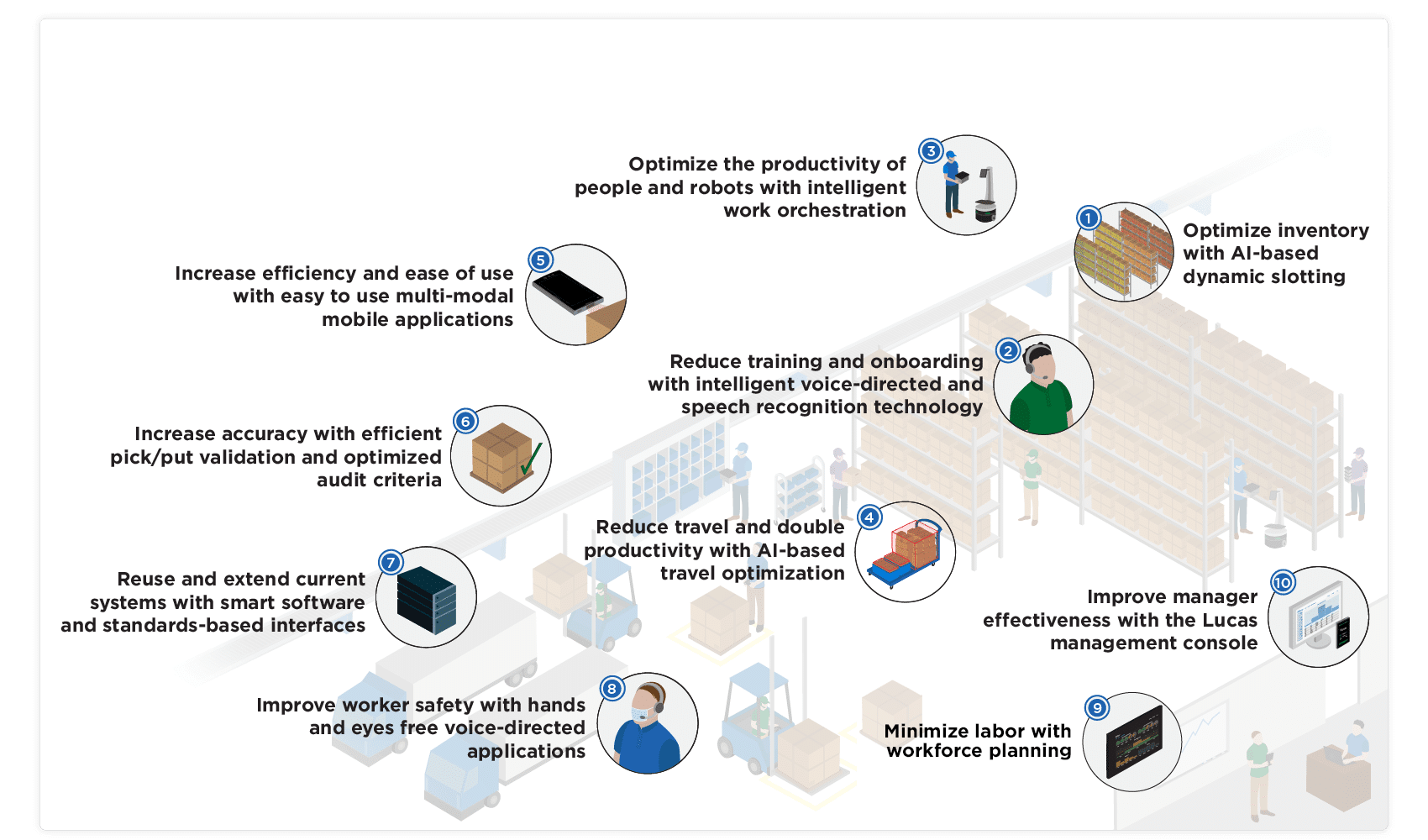

The Lucas Warehouse Optimization Suite helps transform DC operations and continuously adapt to changing markets and customer demands, improving throughput, productivity, and service by orchestrating and optimizing resources – people, robots, inventory – across IT and automation systems.

Flexible and Future Proof for IT and Operations

Through voice, AI-based optimization, adaptive workflows, and a micro-services architecture, Lucas warehouse optimization software empowers companies to meet new demands by setting new standards for employee productivity and accuracy, improving management effectiveness, and evolving with your business.

+The easy-to-use Lucas mobile application runs on the mobile device of your choice. The user interface combines voice direction (Jennifer™ voice), speech recognition, scanning, display and RFID to help automate any manual, hands-on process in the warehouse.

+Jennifer™ utilizes AI and advanced algorithms to enable managers to make efficient slotting moves in advance of changing conditions.

+Reduce training and onboarding with easy to use voice-directed mobile applications incorporating industry leading dual recognition speech technology.

+The Lucas management console provides managers real-time visibility and control of operations to help increase throughput and manage peaks. Beyond monitoring operations, managers can manage workers and work in process, and update rules, settings and configurations.

+The Lucas system leverages rich and granular data and Jennifer™ applies advanced machine learning algorithms to provide managers with advanced workforce planning and performance management capabilities.

+Jennifer™ provides AI-based intelligent batching and pick path optimization that reduces travel, increases pick density, and dramatically increases productivity. In addition, Jennifer™ enables advanced task interleaving and continuous order streaming.

+Deliver the right products to your customers with efficient pick and put validations, optimized QC/audit criteria and Jennifer’s on demand assistance.

+Lucas enables you to seamlessly integrate next-generation technology with enterprise software, robotics and warehouse automation, reducing the costs and risks of change.

+Voice-directed applications allow operators to be eyes and hands free, making them more aware of surroundings. Operations that add voice solutions often see a decrease in accidents.

+While Jennifer™ orchestrates and optimizes within picking zones, a DC can add robots for conveyance between pick zones or other staging locations. This can further reduce worker travel to and from fixed drop off or induction points. Likewise, Jennifer™ can be used to optimize the travel of robots for full pallet moves, both in inbound and outbound operations.

+The easy-to-use Lucas mobile application runs on the mobile device of your choice. The user interface combines voice direction (Jennifer™ voice), speech recognition, scanning, display and RFID to help automate any manual, hands-on process in the warehouse.

+Jennifer™ utilizes AI and advanced algorithms to enable managers to make efficient slotting moves in advance of changing conditions.

+Reduce training and onboarding with easy to use voice-directed mobile applications incorporating industry leading dual recognition speech technology.

+The Lucas management console provides managers real-time visibility and control of operations to help increase throughput and manage peaks. Beyond monitoring operations, managers can manage workers and work in process, and update rules, settings and configurations.

+The Lucas system leverages rich and granular data and Jennifer™ applies advanced machine learning algorithms to provide managers with advanced workforce planning and performance management capabilities.

+Jennifer™ provides AI-based intelligent batching and pick path optimization that reduces travel, increases pick density, and dramatically increases productivity. In addition, Jennifer™ enables advanced task interleaving and continuous order streaming.

+Deliver the right products to your customers with efficient pick and put validations, optimized QC/audit criteria and Jennifer’s on demand assistance.

+Lucas enables you to seamlessly integrate next-generation technology with enterprise software, robotics and warehouse automation, reducing the costs and risks of change.

+Voice-directed applications allow operators to be eyes and hands free, making them more aware of surroundings. Operations that add voice solutions often see a decrease in accidents.

+While Jennifer™ orchestrates and optimizes within picking zones, a DC can add robots for conveyance between pick zones or other staging locations. This can further reduce worker travel to and from fixed drop off or induction points. Likewise, Jennifer™ can be used to optimize the travel of robots for full pallet moves, both in inbound and outbound operations.

(Hover over each item to learn more)

Optimize the Most Important Processes in Your Warehouse

The Warehouse Optimization Suite is based on thousands of person-years of operations experience in hundreds of DCs. The suite features Jennifer™, the brain, voice, and orchestration engine that drives performance improvement gains. Jennifer™ incorporates a variety of AI, machine learning, and other decision making technologies that are used to optimize and orchestrate DC operations.

What Makes Lucas Warehouse Optimization Suite Different?

For the last 25+ years, hundreds of warehouses worldwide have been transformed using Lucas warehouse optimization tools. Every solution incorporates smart software, flexible technologies, and a consultative implementation approach led by warehouse optimization experts.

Trusted by Industry Leaders

Get Started With These Helpful Resources

Three Steps to Creating a More Productive DC

This guide takes you through three steps that have helped hundreds of distribution centers worldwide increase productivity and throughput in their picking processes.

Warehouse Travel Reduction Guide

This guide looks in depth at how different approaches to implementing voice determine the magnitude of productivity gains any facility may achieve. Use the guidelines in this paper to estimate the potential results in your DC.

AI-based travel optimization

This 10-minute demo dives into the various components of our AI-based optimization tool – dynamic prioritization, path optimization, and intelligent batching. Fill out the form and we will send you the demo.

We helped Baptist Health, a leading healthcare provider, double picking productivity.

“The previous average picking rate in the LUM area was 50-56 lines per hour (LPH). Today it is 100-110. That is a 100% improvement, and in bulk picking, the number is about 20 percent.”

We helped Apex Tool Group, a leading manufacturer of hand and power tools, operate with 10% fewer man hours.

“You rarely implement a new system and have users tell you ‘It’s made my life so much easier!’ Making the processes better for associates makes them more productive. And that’s better for the business.”