Predictive analytics is a component of advanced analytics which utilizes data mining, artificial intelligence, machine learning and data modeling to enhance warehouse and DC managers with data to be proactive and make predictions about future events.

Predictive analytics provide dynamic slotting and workforce planning management tools to make warehouse workers more efficient, productive and happy.

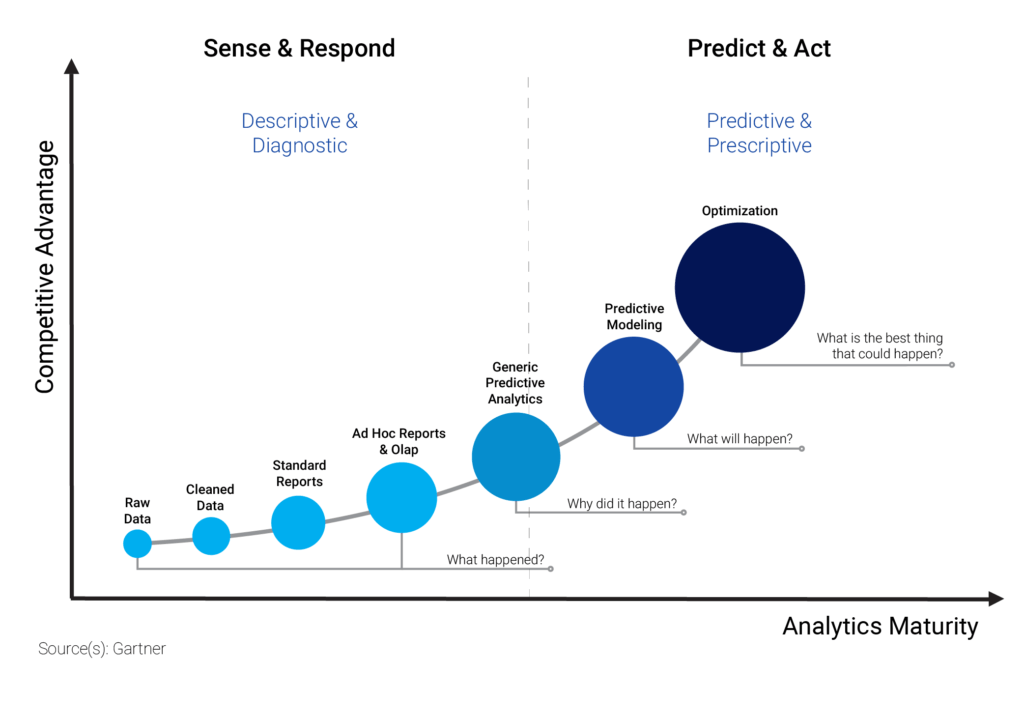

Most Analytics are Reactionary

Most often, analytics are providing warehouse and DC managers with historical data that is out-dated and useless. The state of most operations will have changed significantly since the data was received and analyzed. If someone is manually going in to the database and extracting the necessary data, the decision made based off that data may no longer be worthwhile.

Warehouses and DCs need data that is predictive rather than reactionary. However, this is not always easy and takes appropriate ML and AI based solutions.

Predictive and Prescriptive Analytics With Machine Learning

People are heavily utilized in the process of machine learning. Data isn’t simply handed over to a computer to make sense of, it’s a process that were involved in. There are a few steps taken to successfully create a successful model.

- Data lakes – Data lakes are a way for us to take all the data we know we have available and throwing it somewhere, we don’t know what we want to do with it yet, but let’s just put it somewhere and then we’ll figure out what we’re going to do with it.

- Cleansing the Data – Next, with data warehouses, business knowledge is placed on top of the data and structed to prepare it to move up the curve.

- Machine Learning and AI – How do we get to the point where we’re being pro-active? Predictive and prescriptive analytics, through machine learning, artificial intelligence and data science.

Machine learning algorithms allow us to make predictions once they are applied to the data we had ingested into the system. However, These models we build aren’t just generic models. Machine learning models target specific use cases and problems.

If you don’t understand what you’re trying to fix and don’t understand the business problems you’re trying to solve you can’t build an appropriate model. Data scientists and warehouse managers will collaborate, define what’s important, and build an appropriate machine learning model. A computer only can learn from what it’s told, it doesn’t go off and do it itself.

Building on Knowledge to Develop Effective Machine Learning Models

Machine learning models are driven by experience. As warehouses and DC’s continue daily operations, the models will constantly adapt and learn from the data. What’s learned today is going to be different than a week from now, but somebody’s not manually pulling the data and drawing conclusions themselves. The machine learning model is trained to constantly take that data and adapt to what it learns. Seasonality will be learned through the model over time.

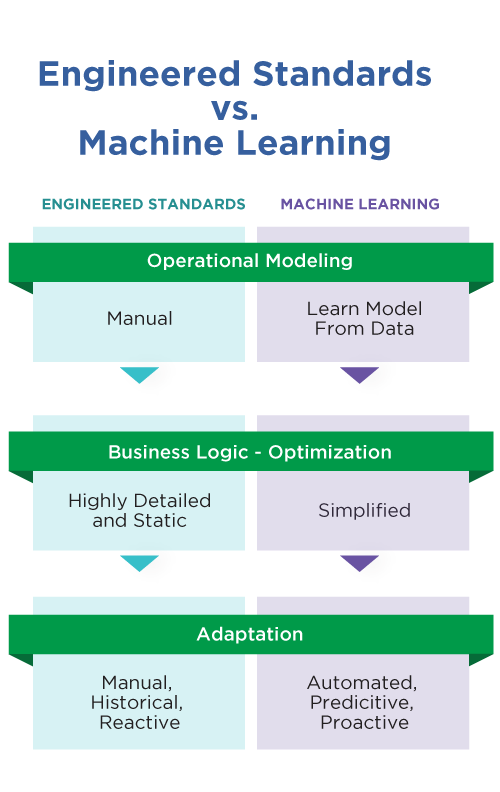

Engineering Standards vs. Machine Learning

Engineering standards have helped us measure performance & productivity. Though they have been effective and reliable, they are costly and unable to adapt to changes in an operation. By changing the layout of the warehouse, product mix, or move to e-commerce, what happens? Engineering standards are now out of date and cost extra to re-configure new standards.

With machine learning, the model adapts to those changes automatically, as long as we keep feeding it data. Operations are going to keep sending data in to our model and it’s going to keep learning and give us better optimizations based off of the current state.

Machine Learning Use Cases

To increase throughput, machine learning & predictive analytics can be leveraged to provide efficient dynamic slotting and workforce planning and management.

1) Dynamic Slotting

Many warehouse and DC operators have invested in slotting software. However, slotting is reactive and not predictive or prescriptive. Historical data can show the last six months of our high velocity products – what are the slow-moving SKUs and where can we slot those products? But the last 6 months doesn’t guarantee the next 6 months.

Allowing the injection of current data now allows us to make better decisions. By feeding a sales forecast into a machine learning model, slotting can be tweaked based off of future information rather than historical. See an example of dynamic slotting in action.

Slotting looks at current events, workforce, etc. That information and data can help change the decisions in a model. By utilizing that data and injecting it into the system automatically our slotting approach is dynamic rather than static.

Machine learning allows for presenting optimizations based off learnings, but also provides levers that can say:

- “What if this changes over the next few months?”

- “What if I want to prioritize replenishment over picking?”

- “What if I’m worried about safety and congestion in the warehouse?”

Machine learning allows us to play “what if” scenarios and have the model regenerate optimization scenarios off it.

2) Workforce Planning

Machine learning models allow us to look at the productivity of workers and determine whether or not we can finish an order on time. By predicting what we have to do in terms of workforce, we can get our workforce in the right position so we can guarantee orders are going out on time.

Proactiveness allows warehouses and DC managers to find areas in which productivity rates are low. The manager may determine this to be a slotting issue rather than unproductive pickers. Having this visibility allows warehouse and DCs to get the most out of their associates – increasing productivity rates, accuracy, and employee morale.

Be Future Ready With Predictive Analytics

Predictive analytics allows us to find and stop problems before they occur. We can adapt to differences across sites, we can see why one site is not performing against another one and try to make changes as a result.

In addition, machine learning models are less expensive than traditional engineering standards because we’re not going out and redoing the standards every time. The model is built, the data is there, and once the pipelines are built to inject the data, the model learns and adapts. There may be tweaks here and there, but the systems is built for that.

By using predictive analytics to combine dynamic slotting and workforce planning, we’re setting up workers for success. We are setting them up to be happier. Happy workers, more productive, better for business, better for costumers, it’s all connected.