Autonomous mobile robots, or AMRs, are the latest trend in warehouse automation. Ecommerce companies, traditional retailers, and 3PLs view AMRs as a key technology to rein in the high labor costs associated with ecommerce fulfillment.

This article describes five different applications and types of AMRs used in the distribution center. While these new warehouse AMRs have far lower capital costs than traditional warehouse automation, they are by no means low-cost solutions. To learn more about the costs and ROI of AMRs in the distribution center read our recent post, “The ROI of Autonomous Mobile Robots in Your DC”.

Warehouse Robots for Transport

AMRs use many of the same technologies as self-driving cars and trucks. Scores of start-up robotics companies are applying these autonomous driving technologies in a variety of robotic solutions for the warehouse and distribution market.

Other companies are developing robotic arms and/or grippers of various types for picking products. And some companies are creating robots that can both pick and transport goods in a DC. These pick and transport robots are still early in their development.

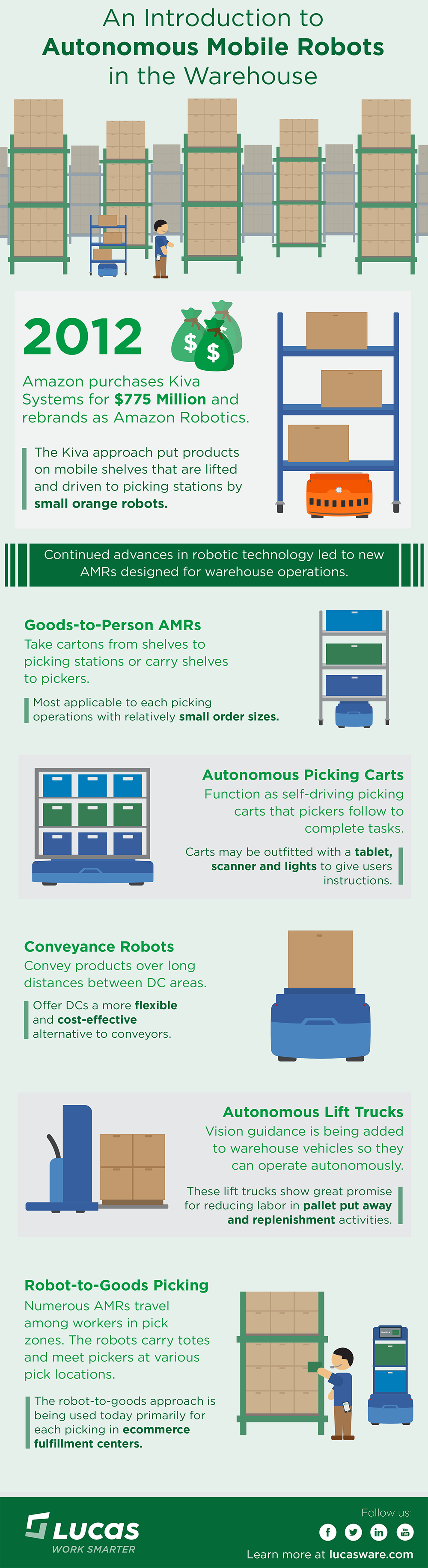

Kiva Breaks the Goods-to-Person Mold

Kiva Systems was the earliest and best-known warehouse robotics start-up. Amazon purchased Kiva in 2012, ceased external sales of the Kiva robots, and rebranded it Amazon Robotics.

Kiva had pioneered the market by offering a new approach to goods-to-person picking. Unlike previous AS/RS-based goods-to-person systems, the Kiva solution put products on mobile shelves that are lifted and driven to picking stations by small orange robots. Amazon has installed thousands of these robots in its FCs.

The fleet of Amazon robots can present a new product at a pick station every six seconds. A worker at the pick station retrieves the required item from the shelf and confirms his pick on a computer screen. The maximum potential picking rate for the Kiva/Amazon system is around 600 picks per person/hour. (By comparison, high density pick modules have maximum pick rates of upwards of 1000 picks per person/hour, although for smaller numbers of products.)

Kiva demonstrated the advantages of AMRs over conventional fixed automation systems for ecommerce operations with very large SKU counts processing high volumes of small orders. Not all products or operations are a fit for this style of automation, however. Amazon itself continues to build a mix of fulfillment centers. Many use the orange Amazon Robotics bots, and others use more conventional picking processes, including pick-to-cart from static shelving.

Advances in robotic technology over the past ten years have led to a proliferation of new autonomous mobile robots. These solutions fit into five different categories, including goods-to-person systems.

Five Categories of Autonomous Mobile Robots

1) Goods-to-Person AMRs

Building on Kiva’s legacy, today’s goods-to-person AMRs take two forms: some that take cartons from shelves to picking stations and others that carry shelves to pickers. Like Kiva, these solutions are typically paired with dedicated pick-pack stations. They are most applicable to ecommerce picking operations with very large SKU counts and small order sizes.

2) Autonomous Picking Carts

Some AMR systems function as self-driving picking carts that pickers follow to complete their jobs. The carts may be outfitted with a tablet, scanner and lights to give users picking instructions and confirm activities. These AMRs save users travel time moving carts to and from picking zones, but they do not measurably impact travel within the picking area itself. In some cases, the top rates for pickers using autonomous picking carts may be less than the rates for pickers using an optimized picking process with traditional push carts.

3) Conveyance Robots

Several start-up companies are offering robots that convey products over long travel distances between DC areas. These conveyance robots offer DCs a more flexible and cost-effective alternative to conveyors or traditional AGVs.

Conveyance AMRs are an ideal complement to systems and technologies that maximize conventional picking processes within picking zones – like the Lucas Warehouse Optimization Suite.

4) Autonomous Lift Trucks

A number of companies are offering a new take on AMRs for full pallet operations. Several start-ups and traditional fork truck manufacturers are adding vision guidance to warehouse vehicles so they can operate autonomously. These self-guided lift trucks reduce labor in the most travel-intensive activities in the DC, like pallet put away and replenishment. These tasks, however, don’t typically require as much labor as each- or case picking operations.

5) Robot-to-Goods Picking

The latest twist on autonomous mobile robots for each picking is robot-to-goods AMRs, or swarming robots. In this approach, numerous AMRs travel among workers in pick zones. The robots carry totes to pick locations and meet workers in the picking area. The human workers pick and place the items in totes based on instructions on a tablet mounted to the deck of the robot. The AMRs may incorporate scanners and put-to-light technology.

The robot-to-goods approach is being used primarily for each picking in ecommerce fulfillment centers. Unlike goods-to-person AMRs, the robot-to-goods model does not completely eliminate human travel.

Comparing Pick Rates of AMRs

Some ecommerce DCs report doubling the productivity of their pickers using robot-to-goods AMRs, with a ratio of three or four robots per picker (this is a similar ratio to goods-to-person AMR systems). The top potential pick rates for robot-to-goods systems is around 300 lines/man-hour, or half of the maximum rates for goods-to-person systems. These pick rates are about the same as you might see in cart-picking operations using batch and pick-path optimization.

Maximum pick rates and the number of robots per picker/packer are key factors in making a cost justification for an investment in warehouse robots. Our next blog entry will look at these and other factors as we examine robot ROI in depth.

Interested in learning more about autonomous mobile robots and humans working in harmony in the DC? Check out one of our recent webinars in our webinar library- “Reducing Travel With Robots and Digital Automation”.