Two weeks ago I started a discussion on LinkedIn about the growing number of DCs that are combining voice and scanning to get the best of both worlds in picking and other warehouse operations. One participant in the discussion agreed that voice and scanning are better together, but he added that “scanning is typically better than speaking back a check digit to confirm a picker is at the right location.” I hear this all the time, and I couldn’t disagree more.

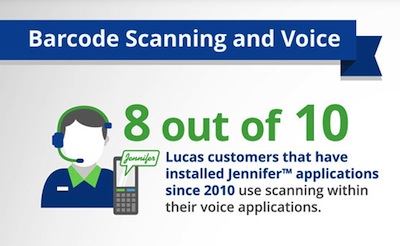

The 400-plus DCs using Lucas multi-modal applications represent a good sample universe to answer this question. Lucas supports voice and scanning interchangeably, so in effect every one of those 400+ DCs have the choice to scan, speak, or to use both to confirm locations. So how did they vote with their actions?

Ninety-nine percent of all DCs using Jennifer use spoken checkstrings to confirm workers are picking from the correct location. The vast majority of these customers use checkstrings printed on a location label, but many use checkstrings printed on the product to be picked (such as the last 3-4 digits of a UPC). This begs another question: If operators who have the choice overwhelmingly pick voice, why is there still a perception that scanning is better?

Can users memorize checkstrings?

I think the “scanning is better” perception is based on an outdated understanding of how checkstrings are used in state-of-the-art voice systems. In the early days of voice, checkstrings were more-or-less permanent, so it was quite possible for users to memorize location checkstrings and pick without visually confirming they were at the correct location.

To prevent memorization, the solution is to periodically change the checkstrings. Jennifer allows managers to change checkstrings on a daily basis (or more) without changing the location labels.

Checkstrings – How do they work?

- Rather than using a three-digit checkstring label on each location, warehouses with Jennifer print five-digit numbers.

- Users are then required to enter a three-digit combination that can be changed as often as managers want.

- On Monday users can be asked to enter the first three digits of the checkstring. On Tuesday they will be asked for the last three, and on Wednesday, the middle three. You can even ask users to enter a combination of digits in reverse (right to left instead of left to right). Changing the checkstrings practically eliminates the possibility of memorization.

DCs can mix and match checkstrings and barcodes to optimize efficiency and accuracy.

Beyond the either/or, checkstring vs. barcode debate, the reality is that there are far more options for confirming locations or items (and thus ensuring accuracy) in a multi-modal system that supports both voice and scanning.

- You could use speech to enter location checkstrings or the last several digits of an item UPC, among others.

- Users could be required to speak the check digits for every location, and then be asked on occasion to scan an item barcode.

Ideally, DCs can mix and match strategies and technologies to optimize efficiency and accuracy. But again, it’s about designing a process and applying the right technology. Neither speech nor scanning is always the best answer.

(As an aside, most people use the words “checkstring” and “check digit” interchangeably. At Lucas we tend to say checkstring since it more accurately describes a string of multiple digits rather than a single check digit.)