Case picking, similar to order picking, involves picking a product in full case or carton quantities from a variety of storage mediums. When pickers are picking in cases, they are typically picking to a pallet, cart, or conveyor.

Where is Case Picking Used?

Case picking is often used in distribution centers that serve retail or ecommerce stores. Most often, third party logistics providers, beverage distributors and big box store providers will devote a section of their warehouse to picking cases.

Increase Case Picking Productivity and Accuracy Through Process Optimization

In many warehouses and distribution centers there is struggle to meet productivity requirements without optimizing their case picking processes.

To get really dramatic levels of efficiency, DCs can reengineer their processes as they implement a voice-directedsystem. This could take the form of introducing dual-pallet picking instead of picking a single pallet at a time, or, if you are already picking multiple orders in a batch, batching work assignments differently to optimize pick density and reduce travel, or moving to a zone picking process.

Download Now: Three Steps a More Productive Distribution Center [Free eBook]

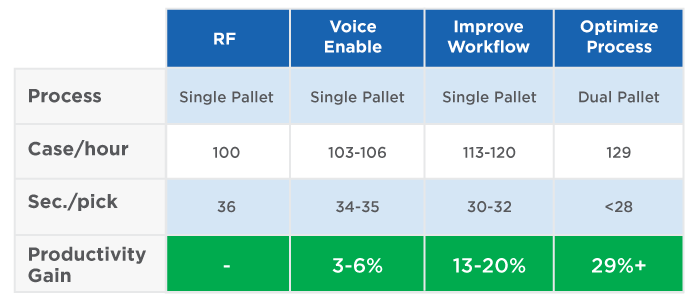

Below is an example of how Lucas warehouse optimization solutions can help a DC significantly increase productivity and accuracy while case picking to a pallet.

Optimize Your Case Pick to Pallet Process to Skyrocket Productivity

The table below illustrates the impact of the different implementation approaches in a hypothetical DC with an average RF pick rate of 100 cases per hour. To keep things simple, we are assuming there is a single case picked per line and that workers are picking a single order at a time to a single pallet.

- In this scenario, voice-enabling an RF application would save 1-2 seconds per pick versus a typical RF workflow by eliminating scanning and screens (column 2).

- Dialogue and workflow improvements (column 3) compound the benefits of eyes and hands free activities, shaving additional seconds from every pick. Additional minutes per day can be saved in exception handling, reduced travel, and in pre- or post-task steps. The table only includes in-task workflow improvements.

- In the process optimization column (column 4), we are assuming the DC is moving from picking cases to a single pallet to picking to two pallets at a time. This effectively doubles the pick density (i.e., the number of picks per picking assignment), cutting travel time per pick anywhere from one-quarter to one-half.

- Doubling the pick density and optimizing the pick workflow would conservatively save eight seconds per pick for a net 29 percent productivity gain (not to mention the potential time savings from streamlining other tasks).

How to Determine an Optimal Strategy for Your Warehouse

As illustrated in this simplified example, it is fairly easy to identify and quantify the time saving from voice-enabling screens and scans in an existing RF process. It is also straightforward to project the productivity benefits of streamlining or improving an existing workflow. It is more challenging to estimate the potential gains from process optimization as that requires a clear picture of what an optimal process will look like in your DC.

A good way to get started in developing a vision for that end-state and for projecting the potential efficiency benefits of a new process, is to conduct an operations assessment. Similar to a lean assessment as part of a six-sigma process, you will need to document how and why you are doing things today to identify specific time-saving opportunities in your existing process.

To help DCs conceptualize their own optimal process – and to begin to estimate your end-state productivity gains – Lucas offers an operations assessment service. The purpose of the assessment is to identify specific process improvement opportunities in your facility. To learn more about our operations assessment click here.

Get Started With These Helpful Resources

Get Started With These Helpful Resources

Voice Picking Software Selection Guide

This guide dives into determining whether voice is right for your warehouse, key benefits and features, hardware options, WMS and ERP integrations and system pricing & implementation costs.

Three Strategies for Leveraging Voice in Your DC

This guide looks in depth at how different approaches to implementing voice determine the magnitude of productivity gains any facility may achieve. Use the guidelines in this paper to estimate the potential results in your DC.

Buyer’s Guide for Mobile Computers for Warehouse Operations

Learn how to choose amongst rugged smartphones, wearables, tablets, smart glasses and warehouse bricks and guns.