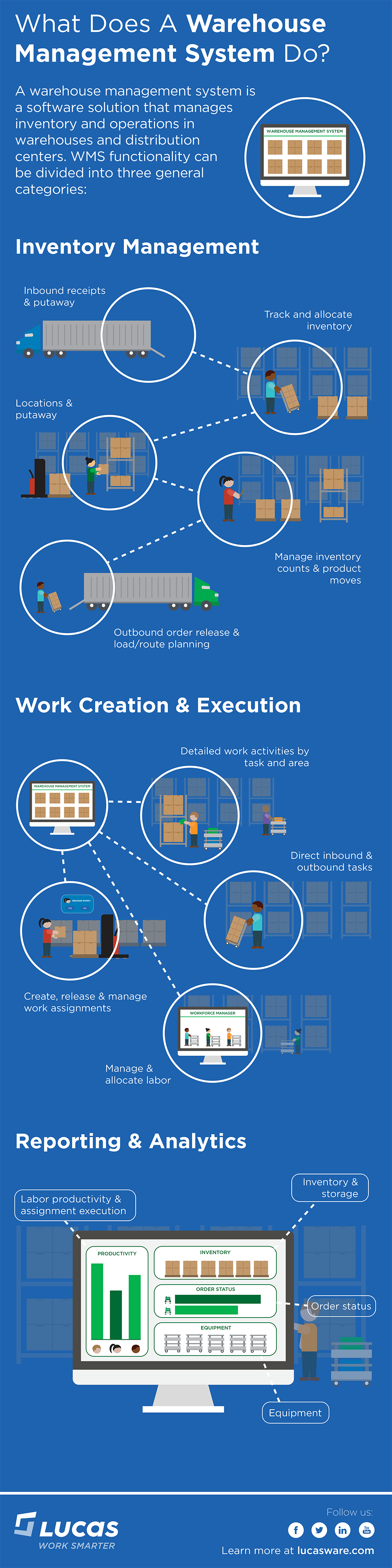

A warehouse management system (WMS) is a software solution that manages inventory and operations in warehouses and distribution centers (DC). WMS functionality can be divided into three general categories – Inventory management, work execution and reporting.

Three Main Functions of a Warehouse Management System

Inventory Management

- Track and allocate inventory within the warehouse or DC

- Manage locations and plan storage.

- Manage inbound receipts and putaway.

- Plan and schedule product moves.

- Plan and schedule product moves.

- Manage outbound order release and load/route planning.

- Plan and manage inventory counts.

Work Creation & Execution

- Plan detailed work activities by task and area.

- Manage and allocate labor by activity and area.

- Create, release and manage work assignments.

- Direct inbound & outbound tasks:

- Receiving, putaway, replenishment, picking, packing, loading, and returns

Reporting & Analytics

- Inventory and storage

- Work, task and assignment execution

- Labor productivity and performance

- Order status

- Equipment

Other Sources for Warehouse Management System Capabilities

While most warehouses and DCs today use a dedicated Warehouse Management System, many rely on the warehouse management and inventory capabilities of other enterprise systems, including ERP, order management systems, or route accounting software (RAS).

As might be expected, different systems offer different levels of capability. For example, many ERP and RAS systems provide basic inventory tracking capabilities (how much inventory of a given product is in the warehouse), but they may not have detailed tracking of inventory to the bin level (what quantity of product is in each location – forward pick location versus overstock, etc.). Bin level tracking is common in most standalone WMS packages.

Common Add Ons For WMS

In addition, it is common for DCs to purchase add-on modules to supplement the basic warehouse and inventory capabilities of their WMS or ERP systems. For example, many warehouses buy standalone labor management systems to provide richer productivity tracking, workforce planning and labor standards tools.

Likewise, it is increasingly common for DCs to supplement their warehouse management system with external slotting or warehouse execution systems. Many DCs use warehouse control systems (WCS) to manage the execution of automated material handling processes.

More and more are adding warehouse optimization solutions to orchestrate and optimize the physical movement of products by people and/or machines, including autonomous mobile robots (AMRs).