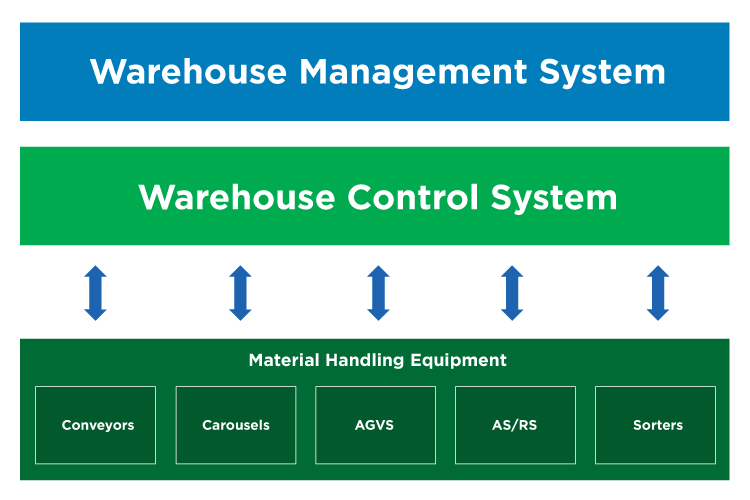

A warehouse control system is a software application used for the management and direction of material handling automation systems within a warehouse or distribution center. Warehouse control systems (WCS) are responsible for ensuring an efficient product flow across different material handling equipment and sub-systems such as conveyors, pick-to-light modules, carousels, sorters, AS/RS systems and AGVs, among others.

In most facilities, the WCS will control the automated material handling equipment and integrate with a warehouse management system (WMS) that will manage and plan warehouse activities from receiving through shipping. The WMS will typically direct the work of material handling staff alongside the automation systems controlled by the WCS. More and more facilities are adding AI-based warehouse optimization solutions to optimize and orchestrate the work of people, WCS systems, and robotics.

What Are The Functions of A Warehouse Control System?

- Exchanging necessary information with the host or WMS to manage automated material handling functions in a warehouse or DC.

- Coordinating activities across various material handling sub-systems.

- Determining the most efficient routing of products and transmitting directives to the equipment controllers.

- Assigning cartons to divert locations.

- Real-time monitoring, controlling and diagnostics of automated systems based on data collected from system-level controllers and sensors.

What Are The Advantages?

- Smooth end-to-end workflow amongst warehouse workers and equipment

- Optimized product routes and improved resource assignment

- Improved visibility in day-to-day tasks

- Increased efficiency of material handling sub-systems

- Storage optimization

How Does A WCS Compare To A WMS?

A warehouse management system specializes in managing the flow of inventory within a company’s distribution center(s), assigning labor tasks and tracking orders from receipt to shipping, as well as reporting capabilities. A WMS, however, does not manage equipment and machines, put-to-light systems, sorters, conveyors, AS/RS, cartons, etc.

Warehouse management systems know the inventory flow of the company as a whole, but it needs a WCS to provide information on where items, cartons and pallets are as they move among automated systems within the four walls of a distribution center or warehouse.

For those who operate a highly-automated facility, warehouse control systems are very important to ensure the site runs smoothly and orders are tracked as they move through the facility on automation systems.

Get Started With These Helpful Resources

Voice Picking Software Selection Guide

This guide dives into determining whether voice is right for your warehouse, key benefits and features, hardware options, WMS and ERP integrations and system pricing & implementation costs.

Three Strategies for Leveraging Voice in Your DC

This guide looks in depth at how different approaches to implementing voice determine the magnitude of productivity gains any facility may achieve. Use the guidelines in this paper to estimate the potential results in your DC.

Buyer’s Guide for Mobile Computers for Warehouse Operations

Learn how to choose amongst rugged smartphones, wearables, tablets, smart glasses and warehouse bricks and guns.