Henry Schein

Learn how Henry Schein dispatches 36,000 orders, 98,000 cartons, and 156,000 line items, ensuring next-day delivery with a remarkable 98%…

Grocery

The largest cooperative food wholesaler to independently owned supermarkets in the United States, serving 1,100 member companies and over 3,400…

Poole Bay Holdings

Poole Bay prides itself on excellent customer service, an ethical approach to business, and a drive for growth. To help…

Silmid

With a key value proposition of providing the on-demand supply of small volume orders primarily via its full service B2B…

Apparel

Apparel retailers optimize DC operations, and improve worker retention with voice technology.

Orgill

Driving fulfillment excellence and a customer promise from start to finish

Baptist Health South Florida

Learn how we helped Baptist Health triple productivity.

Cengage

Learn how Cengage transformed their cost center to a revenue center.

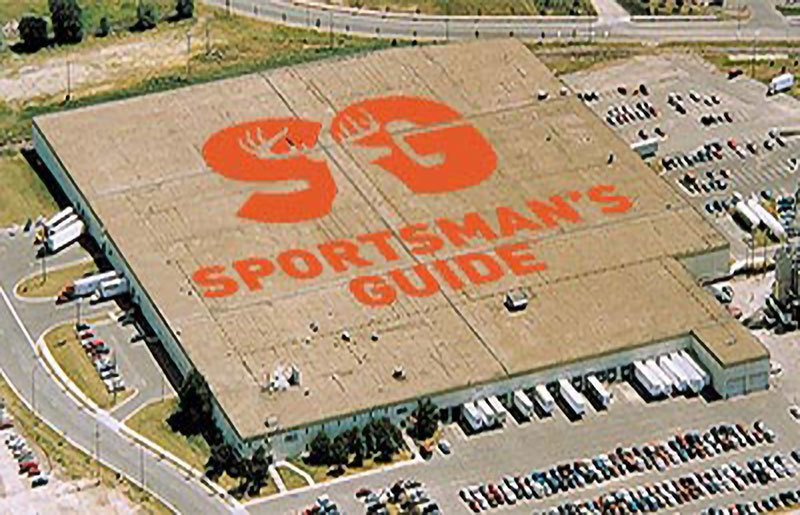

The Sportsman’s Guide

Learn how The Sportsman's Guide reached 99.8% accuracy.

Southwire

Learn how we helped save 2+ hours per day for their DC managers.

Beverage Distributor

A US regional beverage distributor implemented the Lucas solution to replace their legacy technology and improve efficiency and accuracy in…

Rotary Corporation

Learn how Rotary was able to achieve 99.99% same-day shipping while reducing picking hours 25%.