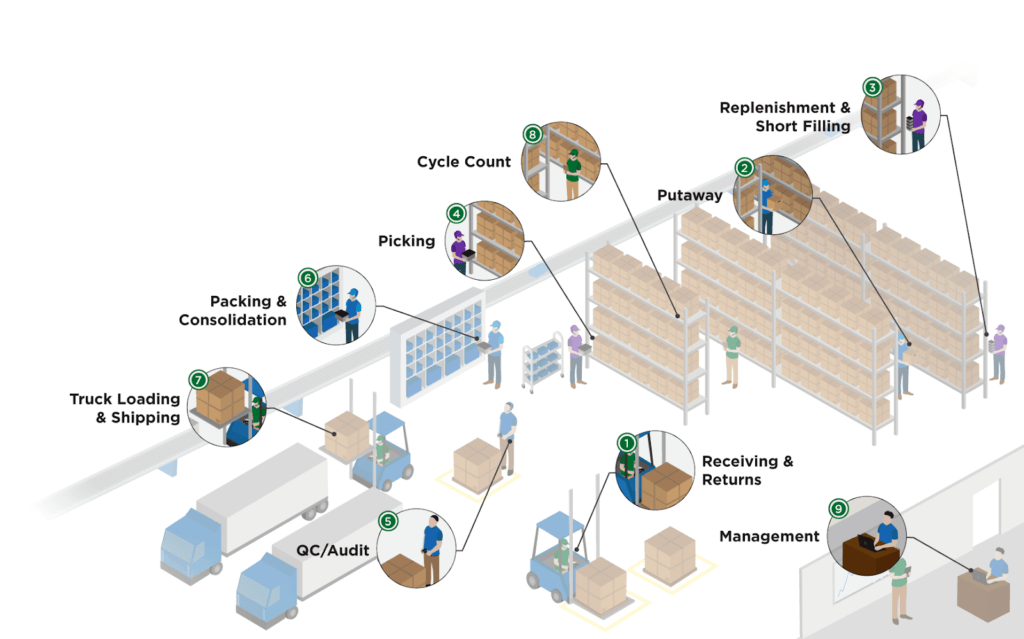

Mobile Apps Designed for Ease and Efficiency

Lucas mobile applications, featuring Jennifer™, streamline hands-on processes for warehouse associates by combining voice, scanning, and vision technologies to improve end-to-end warehouse tasks – from receiving to picking and returns. Best of all, our mobile applications run on rugged smartphones, traditional handheld, wearable and vehicle-mount computers used in the warehouse that connect over wireless networks to warehouse management and other IT systems.

Optimized for Efficiency and Ease of Use

Every Lucas mobile application incorporates best practices gained from thousands of warehouse workers at hundreds of warehouses and distribution centers. And since every DC is different, Jennifer™ adapts to different processes and can support a variety of configurable voice directed workflows, including the flexible use of barcode scanning and other data capture and display technologies – including smartwatches and glasses.

Get Started With These Helpful Resources

Voice Picking Software Selection Guide

This guide dives into determining whether voice is right for your warehouse, key benefits and features, hardware options, WMS and ERP integrations and system pricing & implementation costs.

Struggling to find warehouse workers?

This 10 minute demo dives into the various components of our AI-based optimization tool – dynamic prioritization, path optimization and intelligent batching. Fill out the form and we will send you the demo.

Make Managers More Productive With Machine Learning

Machine learning and AI are expected to have a growing role in warehouse operations over the next five years. This paper is intended to help operations, engineering and IT executives understand what they need to know about this emerging technology, and how it may be used in the near future to improve DC planning and operations.

We helped Baptist Health, a leading healthcare provider, double picking productivity.

“The previous average picking rate in the LUM area was 50-56 lines per hour (LPH). Today it is 100-110. That is a 100% improvement, and in bulk picking, the number is about 20 percent.”

We helped Apex Tool Group, a leading manufacturer of hand and power tools, operate with 10% fewer man hours.

“You rarely implement a new system and have users tell you ‘It’s made my life so much easier!’ Making the processes better for associates makes them more productive. And that’s better for the business.”