Voice picking, also referred to as pick by voice or voice-directed warehousing is a proven process for increasing efficiency and accuracy of pickers in warehouses or distribution centers.

To help understand this technology, we’ve put together this introductory guide that walks through how voice picking works, the benefits, add-ons, features and how to determine if voice technology is right for your operation.

For a more in-depth overview (pricing, implementation, hardware, etc.) download our voice picking guide above.

What is Voice Picking?

Voice picking is a hands-free and eyes-free system that utilizes an intelligent voice agent and speech recognition software to direct associates through their tasks.

As the phrase “voice picking” suggests, organizations initially used these solutions to improve picking operations with voice-only technology. However, today’s voice-directed applications often incorporate complementary technologies like barcode scanning or RFID.

To learn more about complementary technologies used with voice applications, read our post, “Voice Technology Basics”.

How Does Voice Picking Work?

- WMS and ERP Integration: Voice picking software solutions integrate with the DC’s existing WMS or ERP to receive order information, data about the picking areas, etc. (Click here to learn more about WMS/ERP Integration with voice.)

- Associate Setup: Pickers wear headsets with an industrial microphone that connects to a mobile device running the voice application.

- The Voice System Creates Work Assignments: The voice system uses this data to organize and create work assignments or tasks and distribute them to individual order pickers on the warehouse floor. For example, the system may direct the user to pick multiple orders in a batch. (This organization of work – e.g., batching orders – can occur either in the WMS or in the voice system, depending on how the technology is implemented.)

- The Associate Receives Their Work: Once the order picker has their work, the voice system and the picker engage in a fluid dialog that ensures the order picker works as efficiently, safely and accurately as possible.

- The Voice System Instructs the Associate Through Their Work: The voice of the application tells the picker where to go and what to do, such as the warehouse pick location to go to and the quantity of the item to pick. (To see voice in action, watch our “Voice Picking Walkthrough”)

- The Associates Confirms Their Work: The picker speaks into the microphone to confirm their work. The voice picking application includes speech recognition software that recognizes and interprets the order picker’s spoken responses.

- Location Confirmation (For Increased Accuracy & Traceability): Pickers confirm they are picking the correct item by speaking a checkstring to validate the picking location. Or, in some applications, they may speak several digits of a product code or other ID printed on the product.

- Quantity Confirmation (For Increased Accuracy): Pickers also confirm the quantity being picked. The voice application will correct the picker if they enter incorrect information. (To learn more about increasing accuracy with voice confirmations, read our post, “How to Improve Order Picking Accuracy in Your Warehouse”.)

- Continued Work Assignments and Optimized Pick Routes: When the pick is complete, the system will send the associate to the next location until their assignment is complete. Advanced voice-directed solutions will optimize pick paths to further increase productivity and efficiency by reducing travel.

- Data Collected For Managers: Every interaction between the picker and the voice application is tracked so managers are able to view progress of orders as they are picked.

- Management Visibility and Reporting: Advanced work execution systems that include voice technology also have reporting and management tools that complement and extend warehouse management systems (WMS) and labor management systems (LMS).

With these management tools, supervisors and managers manage workflow, react to exceptions in real time, and track and manage productivity and performance. These tools increase the overall effectiveness of warehouse operations more broadly. (Read about our management tools here.)

What are the Benefits of Voice-Directed Picking?

Compared to traditional warehouse order picking processes using paper or barcode scanning, a voice-directed picking system creates a hands-free, heads-up user workflow. Rather than stopping to read, scan, write or punch keys, users listen and speak in a fluid, efficient cadence.

This results in dramatic, direct pay-offs:

- Improve Productivity: Depending on your process (e.g., full case picking from pallets vs. piece picking from flow racks), productivity gains may range from 10-120%. Lucas customers have achieved average picking productivity gains of 36%. (To learn how DC’s have seen up to 120% increases in productivity, read our post, “The Ultimate Guide to Improving Warehouse Order Picking Productivity”.)

- Reduce Errors: Even DCs with 99.99% picking accuracy before voice can reduce picking errors by 25% or more with voice picking.

- Ensure Safety: Because operators are eyes and hands free, they are more aware of surroundings. Operations that add voice solutions often see a decrease in accidents.

- Decrease Training Time: Voice-directed processes are more intuitive for users. Most Lucas customers find that a new associate can be trained and begin going solo in less than a day, and become proficient in one to two weeks.

Ultimately, there are many benefits to a voice-directed solution compared to other semi-automated picking systems. To learn more about how voice compares to pick-to-light systems, RF barcode scanning and automation systems, read our recent post “How Voice Compares”.

What Processes Can Be Optimized With Voice?

Voice applications now help automate any manual, hands-on process in the warehouse. For example, receiving, put away, replenishment, cycle count, sortation, packing, cross-dock, loading, etc.

- Piece Picking: Popular workflows include piece picking to totes or cartons on carts, or on conveyors in a pick module. Variations include bucket-brigade pick and pass systems (zoneless picking), pick-and-put for high volume items, and two-stage picking for slow-moving items.

- Pallet Picking: Full pallet picking, for outbound shipping, can be interleaved with other full pallet moves (cross-docking, replenishment, putaway) to reduce so-called empty travel (when a lift truck is moving from one area to another with nothing on the forks).

- Case Picking: Popular voice picking workflows include case pick to pallet or to conveyor. Although voice picking typically eliminates the need for labels, voice systems can be used alongside labels if that is needed for delivery or other purposes. Some systems also also support two-stage picking processes for slow-moving cases (sometimes referred to as PIR picking – planned inventory reserved).

- Receiving: Voice can be used for receiving mixed or full pallets, including verifying quantities, identifying damage, and for sorting and staging items for put-away. Barcode scanning and visual display information are commonly incorporated in the voice-directed workflow.

- Putaway: Voice-directed putaway can be used for full pallets, mixed pallets (multiple SKUs putaway in separate storage locations), or using carts with mixed SKUs. Barcode scanning is commonly incorporated in the voice-directed workflow, to identify/verify items for putaway.

- Packing & Consolidation: Warehouses that do not have automated sortation systems can use voice to assemble multi-line orders that have been picked in multiple zones or batches. Barcode scanning can be incorporated to identify/verify items. Items may be sorted to locations in a put wall.

- Replenishment & Short Filling: Replenishment can be implemented for moving full pallets or mixed pallets from reserve or bulk storage to forward picking locations. In some instances, replenishment can be included in picking workflows or interleaved with other tasks.

- Truck Loading & Shipping: Warehouses using voice for loading are typically loading pallets for route-stop delivery. Alternatives include system- or user-directed loading, and may include safety and other inspection steps (HACCP, for example). Systems may also support creation of a printed or electronic load map to improve delivery.

- Receiving & Returns: Voice can be used for receiving mixed or full pallets, including verifying quantities, identifying damage, and for sorting and staging items for put-away. Barcode scanning and visual display information are commonly incorporated.

- Cross Docking: various types of cross dock processes may be supported, including full transfers from receiving to shipping, or moving and sorting to outbound staging destinations.

- Cycle Count: In some instances, cycle count can be included in picking or other workflows, or it can be a separate task. Jennifer supports opportunistic cycle counts (directing a picker to count a location after he or she picks from it).

- QC/Audit: Voice systems may support a quality control/audit process. Intelligent voice systems enable managers to better prioritize which orders are checked with parameter-based criteria (inexperienced workers, orders, product type, and customers).

History of Voice Picking in the DC

Today, voice assistance is widely accepted as a way to improve efficiency and usability across many daily activities.

The warehousing and distribution industry has been ahead of the curve in using voice technology to improve manual tasks. Specifically, warehouses have used voice picking for decades to improve worker efficiency.

The early adopters of voice in warehouses had to work around the limitations of the speech recognition of the time. Nevertheless, even the early applications of voice in supply chain led to improved productivity of order pickers and warehouse operators.

Since the late 1990’s, speech recognition has matured. As consumer applications of voice have skyrocketed, tech leaders are pouring millions into improving recognition accuracy. While this consumer application of the concept has led to many advancements, there is still a gap between consumer software and industrial speech recognition required in processes like order fulfillment.

To achieve near-perfect recognition accuracy required in voice-directed picking processes, engines must be tuned for industrial use. Voice recognition software must adapt to the noisy environment, changing conditions and varied accents found in most DCs.

Adding Scanning, Vision and Smarts to Voice Solutions

Early voice picking systems voice-enabled existing paper or RF-based workflows. Today’s advanced voice picking software incorporates flexible, configurable process flows. These systems combine speech recognition with barcode scanning and other input or display tools, including smart glasses.

These so-called multi-modal solutions optimize efficiency and also help companies meet product traceability goals by using advanced data capture tools.

For example, Lucas multi-modal voice-directed solutions deliver bigger improvements in efficiency, productivity, and inventory accuracy, and larger reductions in shipping errors than are possible with simple voice-enabled system.

How to Decide if Voice is Right for My Warehouse?

Voice-directed applications are used primarily in warehouses and distribution centers that are shipping products by the care or less than case quantities.

DCs that only receive and ship full pallets sometimes use voice, although the productivity benefits of voice compared to other technologies (RF, or barcode scanning) may be minimal due to the large amount of travel involved in full pallet moves within a DC.

Other factors to consider to determine if voice is a good fit for you operation:

- Industry: Tens of thousands of warehouses and distribution centers around the world today use voice for outbound product distribution, direct-to-consumer ecommerce fulfillment, and for parts picking and kitting for production operations. Voice can be used for almost any product type ranging from apparel to nuts and bolts, and including items picked and shipped by weight, or length (wire coil, for example). Industries using voice today include, but are not limited to:

- Facility Size: Warehouses and distribution centers ranging from 50,000 ft² to 1 million ft² or larger are great candidates for voice.

- Number of SKUs: The minimum number of SKUs is around 300-500. There is no upper limit as some manufacturing facilities using voice have more than 1 million individual parts.

- Number of Selectors/Pickers and Other Voice Users: Most DCs using voice have at least 10 concurrent pickers per shift. There is no upper limit to the number of users in a single facility.

Read our customer stories to see examples of warehouses and DCs that have successfully implemented voice in their facilities.

Implement Voice-Directed Picking in Your Warehouse Today

Since 1998, we’ve helped over 500 warehouses and DCs dramatically increase worker productivity, operational agility and accuracy with our intelligent voice applications, featuring Jennifer™.

We’d love to do the same for you and get you started, you can schedule a call with one of our voice experts here.

Voice Picking Resources Mentioned in This Article:

- [Ebook] Voice Picking Guide

- [Video] Voice Picking Walkthrough

- The Ultimate Guide to Improving Warehouse Order Picking Productivity

- How to Improve Order Picking Accuracy in Your Warehouse

- How Voice Compares

- WMS/ERP Integration with Voice

- [Ebook] The Evolution of Speech Recognition Technology in the Warehouse

- Voice Picking Technology Basics

- Improve Audit Effectiveness and Reduce Costs with Parameter-Based Auditing

- The Benefits of Voice Picking

- Voice-Directed Put Walls for Ecommerce Fulfillment

- The Lucas Management Console

- Lucas Mobile Applications

- Reduce Picking Travel with AI-Based Travel Optimization

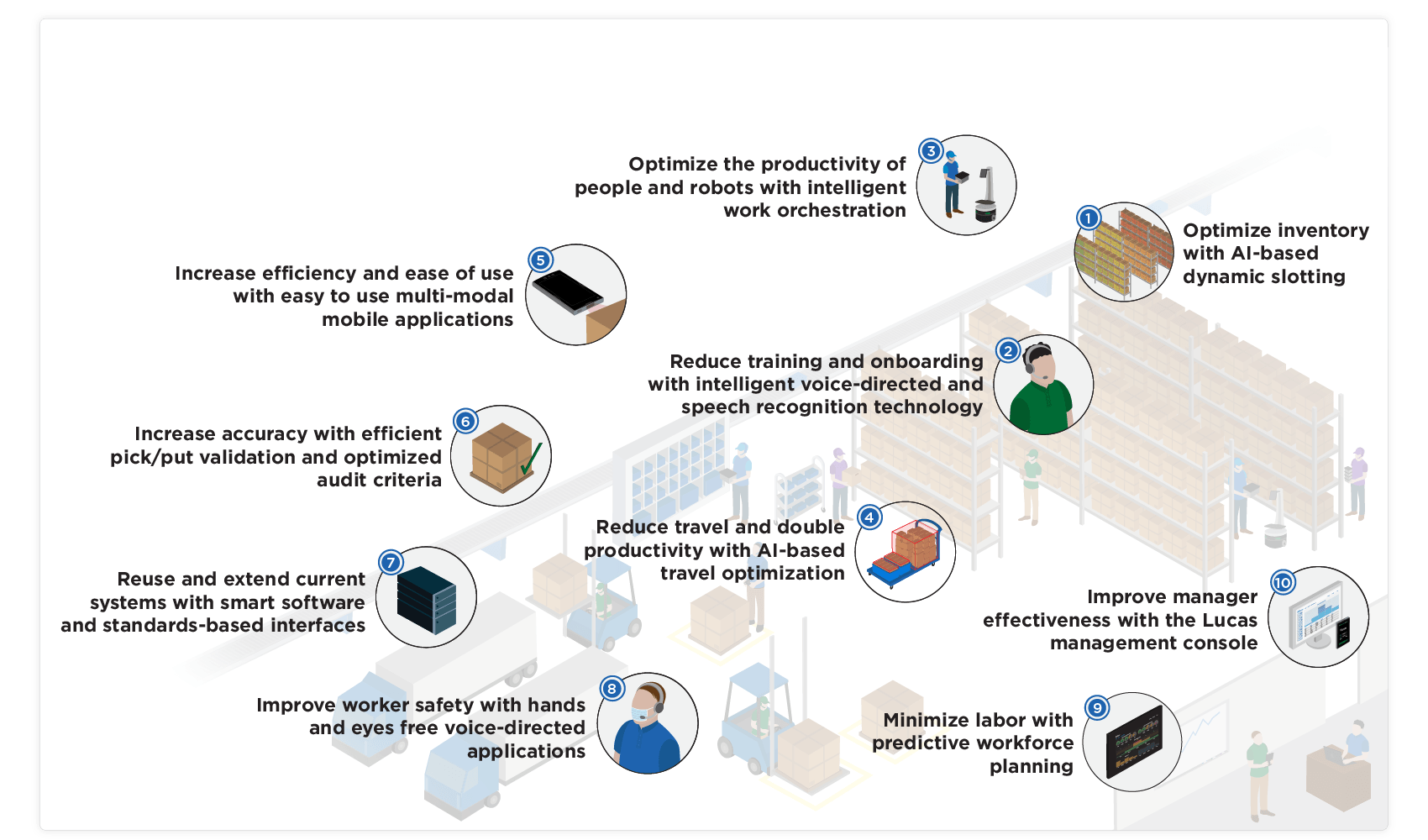

+The easy-to-use Lucas mobile application runs on the mobile device of your choice. The user interface combines voice direction (Jennifer™ voice), speech recognition, scanning, display and RFID to help automate any manual, hands-on process in the warehouse.

+Jennifer™ utilizes AI and advanced algorithms to enable managers to make efficient slotting moves in advance of changing conditions.

+Reduce training and onboarding with easy to use voice-directed mobile applications incorporating industry leading dual recognition speech technology.

+The Lucas management console provides managers real-time visibility and control of operations to help increase throughput and manage peaks. Beyond monitoring operations, managers can manage workers and work in process, and update rules, settings and configurations.

+The Lucas system leverages rich and granular data and Jennifer™ applies advanced machine learning algorithms to provide managers with advanced workforce planning and performance management capabilities.

+Jennifer™ provides AI-based intelligent batching and pick path optimization that reduces travel, increases pick density, and dramatically increases productivity. In addition, Jennifer™ enables advanced task interleaving and continuous order streaming.

+Deliver the right products to your customers with efficient pick and put validations, optimized QC/audit criteria and Jennifer’s on demand assistance.

+Lucas enables you to seamlessly integrate next-generation technology with enterprise software, robotics and warehouse automation, reducing the costs and risks of change.

+Voice-directed applications allow operators to be eyes and hands free, making them more aware of surroundings. Operations that add voice solutions often see a decrease in accidents.

+While Jennifer™ orchestrates and optimizes within picking zones, a DC can add robots for conveyance between pick zones or other staging locations. This can further reduce worker travel to and from fixed drop off or induction points. Likewise, Jennifer™ can be used to optimize the travel of robots for full pallet moves, both in inbound and outbound operations.

+The easy-to-use Lucas mobile application runs on the mobile device of your choice. The user interface combines voice direction (Jennifer™ voice), speech recognition, scanning, display and RFID to help automate any manual, hands-on process in the warehouse.

+Jennifer™ utilizes AI and advanced algorithms to enable managers to make efficient slotting moves in advance of changing conditions.

+Reduce training and onboarding with easy to use voice-directed mobile applications incorporating industry leading dual recognition speech technology.

+The Lucas management console provides managers real-time visibility and control of operations to help increase throughput and manage peaks. Beyond monitoring operations, managers can manage workers and work in process, and update rules, settings and configurations.

+The Lucas system leverages rich and granular data and Jennifer™ applies advanced machine learning algorithms to provide managers with advanced workforce planning and performance management capabilities.

+Jennifer™ provides AI-based intelligent batching and pick path optimization that reduces travel, increases pick density, and dramatically increases productivity. In addition, Jennifer™ enables advanced task interleaving and continuous order streaming.

+Deliver the right products to your customers with efficient pick and put validations, optimized QC/audit criteria and Jennifer’s on demand assistance.

+Lucas enables you to seamlessly integrate next-generation technology with enterprise software, robotics and warehouse automation, reducing the costs and risks of change.

+Voice-directed applications allow operators to be eyes and hands free, making them more aware of surroundings. Operations that add voice solutions often see a decrease in accidents.

+While Jennifer™ orchestrates and optimizes within picking zones, a DC can add robots for conveyance between pick zones or other staging locations. This can further reduce worker travel to and from fixed drop off or induction points. Likewise, Jennifer™ can be used to optimize the travel of robots for full pallet moves, both in inbound and outbound operations.

Get Started With These Helpful Resources

Get Started With These Helpful Resources

Voice Picking Software Selection Guide

This guide dives into determining whether voice is right for your warehouse, key benefits and features, hardware options, WMS and ERP integrations and system pricing & implementation costs.

Three Strategies for Leveraging Voice in Your DC

This guide looks in depth at how different approaches to implementing voice determine the magnitude of productivity gains any facility may achieve. Use the guidelines in this paper to estimate the potential results in your DC.

Buyer’s Guide for Mobile Computers for Warehouse Operations

Learn how to choose amongst rugged smartphones, wearables, tablets, smart glasses and warehouse bricks and guns.